Foundry

A good employer constantly tries hard to improve the terms of employment for their employees. In foundries and smithies this is one particularly challenging subject. Heavy physical shift-work, noise, heat and dust, as well as the ever-increasing time pressure to perform put a great strain on the workplace. Our application solutions are individually specialised arrangements, with or without robots.

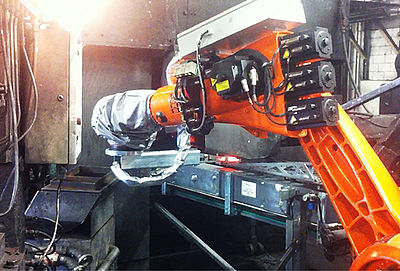

Due to the extreme demands on the automation process, it is unthinkable to operate a system that doesn’t use robots these days. Today, thanks to our modern and refurbished used robots, manufacturing automation has also become feasible for small and medium foundries. The robots used in foundries have a special coating which takes the rough and tough working environment into account and can be used during spraying, insertion, or casting, as well as with the withdrawal of the forms. Their main utilisation possibilities with regard to reach and weight can be adapted well to suit the requirements of your enterprise. The assembly of a robot on a die-casting machine helps to save space, secures access to the machine and optimises cycle times.

It is not only in the casting area that our robots can eliminate the weak points in the process chain and improve your productivity, flexibility and availability. With that you gain a competitive edge in the market.

Heat, dirt and noise also make forges one of the most arduous workplace surroundings in the modern manufacturing age. Humane terms of employment are hard to achieve. Only robot-based automation guarantees a smooth and continuous running process and a constant temperature profile with low tool wear. In addition, the precise setting down of parts of varying forms is enabled by custom-designed software. The heat-insulated robot grip arms are resistant to extreme heat and with their protection they assure precise tool control.